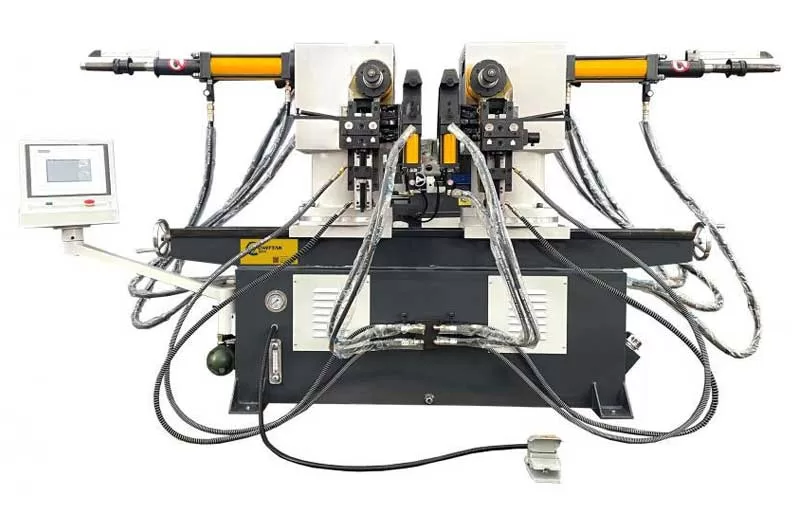

Electric CNC Pipe and Tube Bender

Model No. : CTK-75CNC-4Z-2S

Payment Type : T/T, Others

Incoterms : FOB, CIF, EXW

Min. Order : 1 Set

Transportation : Ocean

Port : Foshan Port, Guangzhou Port, Shenzhen Port

Two-station bending capability

Incorporates a two-station bending capability, optimizing production efficiency by reducing cycle times.

Ensures continuous workflow with a seamless transition between bending stations.

Advanced safety protocols

Integrates advanced safety features tailored for electric CNC bending environments, prioritizing operator safety.

Complies with stringent safety standards, ensuring a secure working environment during bending operations.

Precision sngular bending

Demonstrates precision in angular bending, meeting the demands of industries with specific requirements for precise angles in pipe and tube profiles.

Versatile across a range of bending needs, offering accuracy in angular profiles through electric CNC precision.

Robust construction for longevity

Boasts a robust and durable construction designed to withstand the demands of electric CNC bending operations.

| Max. Bending Diameter for Carbon Steel | Q235 Ф75mm * 2.0 |

| Max. Bending Radius | R300mm |

| Min. Bending Radius | Based on the pipe diameter |

| Min. Bending Angle | 190° |

| Standard Core Length | 3000mm |

| The Number of Bends Can be Set Per Pipe | 20 |

| Max. Feeding Length | 2500mm |

| Control System | PLC |

| Machinable Material | Carbon Steel |

| Core Components | PLC, Bearing, Motor |

| Power Type | CNC |

| Degree Of Automation | Automatic |

| Solenoid Reversing Valve Brand | Yuken |

| Relief Valve Brand | Yuken |

| Regulating Valve Brand | CLC |

| Sensor Brand | Omron |

| Cylinder Brand | Hualiang |

| Switch Brand | Meanwell |

| AC Contactor Brand | Schneider |

| Thermal Overload Relay Brand | Schneider |

| Certification | GS |

| Warranty Period | 1 Year |

| Core Component Warranty Period | 2 Years |