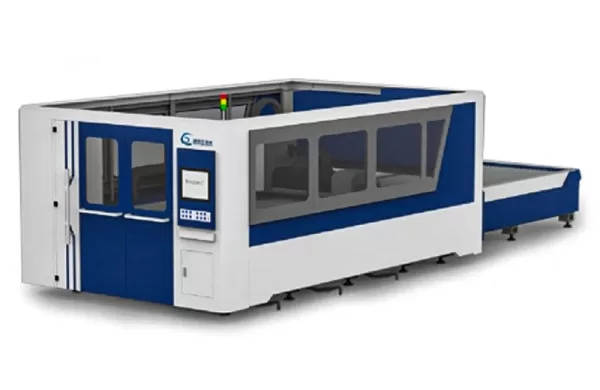

Laser Metal Cutting Machine

Chittak’s full range of laser metal cutting machines are equipped with CNC control systems to better guide and control the movement of the fiber laser beam, improving the accuracy of sheet metal and pipe cutting.

According to different applications, our laser cutting machines can be divided into three types, namely sheet metal laser cutting machines, pipe laser cutting machines and all-in-one laser metal cutting machines for sheet metal and metal pipes.

Laser Metal Cutting Machine Features

Versatility: Our machines can cut pipes of different metal materials (stainless steel, carbon steel, aluminum, iron, brass, copper, galvanized, etc.), shapes (round, square, rectangular, special-shape, I-beam, etc.) and sizes to adapt to various production needs.

Precision Cutting: Advanced focus lens, so that the laser beam can be better focused to a small point, enhance its energy, so as to achieve precise cutting (accuracy up to ±0.05mm).

Speed: The laser beam doesn’t directly contact the workpiece surface, reducing wear and tear, producing clean and burr-free cuts, and improving cutting efficiency.

High Cost Performance: Our machines can replace drilling, milling, sawing, stamping, cleaning burrs and other processes that need different equipment to complete. It can also save material.

- Model: CTK-A9

- Round Tube: φ15mm – φ220mm

- Rectangular Tube / Special-shaped Tube: Circumscribed Circle ≤ φ220mm

- Bus system five-axis linkage, efficiency increased by more than 50%.

- Optional semi-automatic feeding system, cycle feeding time control within 15 – 20 seconds.

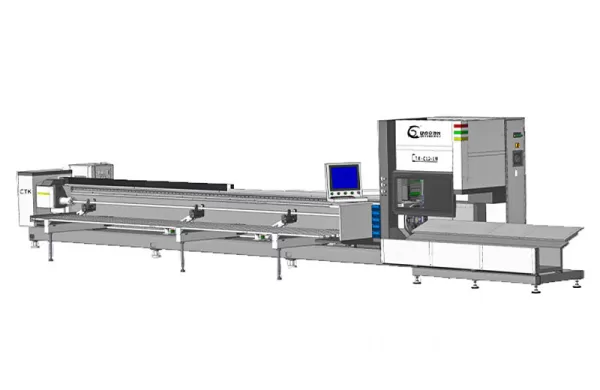

CNC Fiber Laser Cutting Machine

- Model: CTK-C12-LN

- Round Tube: φ10mm – φ120mm

- Square Tube: φ10mm – φ80mm (Side Length)

- Special-shaped Tube: Circumscribed Circle ≤ φ120mm

- High performance Cype Tube control system, interpolation calculation speed, easy to operate.

- Standard column feed system, feed without stopping, can achieve 24 hours non-stop operation.

- Model: CTK-A12-E

- Round Tube: φ8mm – φ120mm

- Square Tube: φ10mm – φ80mm

- Rectangular Tube / Profile / Special-shaped Tube: Circumscribed Circle ≤ φ120mm

- Chuck using lightweight material, automatic precise centering, to achieve high-speed automatic cutting.

- Chuck seal is good, avoid dust entry, low noise, and more durable.

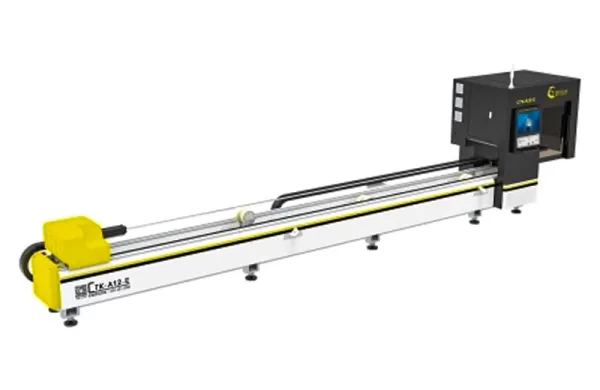

CNC Laser Pipe Cutting Machine

- Model: CTK-A15

- Round Tube: φ15mm – φ160mm

- Rectangular Tube / Special-shaped Tube: Circumscribed Circle ≤ φ160mm

- Reinforced solid bed, after annealing and secondary aging treatment, high stability, suitable for high-speed cutting.

- Fully enclosed chuck prevents iron filings from flying in to protect the chuck.

- Model: CTK-A6

- Round Tube: φ15mm – φ220mm

- Square Tube: φ10mm – φ80mm

- Rectangular Tube / Square Tube / Special-shaped Tube: Circumscribed Circle ≤ φ220mm

- Servo motor precisely controls the stroke to ensure cutting accuracy.

- Patterns can be drawn directly on the system interface to improve production efficiency.

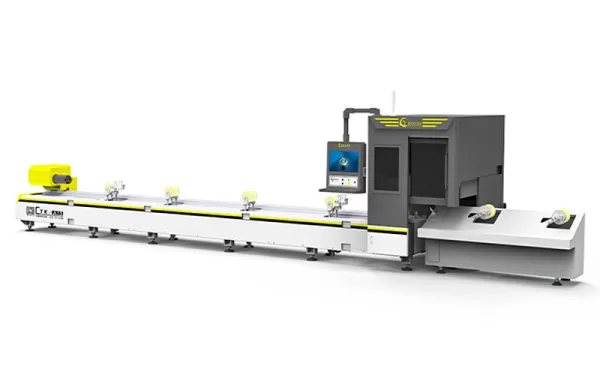

CNC Laser Tube Cutting Machine

- Model: CTK-A12

- Round Tube: φ8mm – φ120mm

- Square Tube: φ10mm – φ80mm

- Rectangular Tube / Profile / Special-shaped Tube: Circumscribed Circle ≤ φ120mm

- Rich pipe processing data, easy to operate.

- High rigidity thickened bed with high-speed bus system, reduce costs and increase efficiency.

CNC Tube Laser Cutting Machine

- Model: CTK-A6-E

- Round Tube: φ15mm – φ220mm

- Rectangular Tube / Square Tube / Special-shaped Tube: Circumscribed Circle < φ220mm

- High cutting precision, smooth cuts.

- Professional full-stroke pneumatic chuck, accurate and efficient.

- Model: CTK-H1

- Elbow Pipe: φ15mm – φ108mm

- Straight Pipe Length: ≤640mm

- The 3D pattern can be modified at any time, saving the cost of making and modifying the stamping die.

- The slag extraction module can automatically remove the iron slag on the inner wall when cutting, so that the inner wall is smooth and clean.

Fiber Laser Cutting Machine for Metal

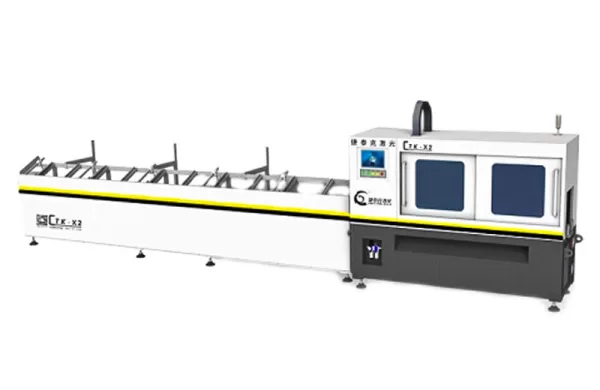

- Model: CTK-X2

- Round Tube: φ10mm – φ65mm

- Processing Length Range: φ15mm – φ1000mm (Other lengths can be customized)

- Cutting Speed: 12m / min (Depending on the material and thickness)

- GXL large stroke oil and gas pressure rotary chuck, fast clamping speed, improve efficiency.

Fiber Laser Metal Cutting Machine

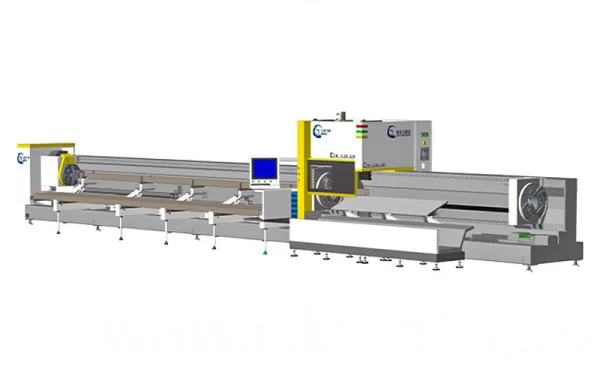

- Model: CTK-C22-LN

- Round Tube: φ12mm – φ220mm

- Square Tube: φ12mm – φ160mm

- Manual Feeding Length: 7000mm

- Automatic Feeding Length: 5800mm ~ 6500mm (Non-standard 5000mm ~ 7000mm)

- Model: CTK-X5-LD

- Round Tube: φ16mm – φ115mm

- Processing Length Range: φ15mm – φ1000mm (Other lengths can be customized)

- Cutting Speed: 12m / min (Depending on the material and thickness)

- Automatic feeding system, the operator only need to lay the pipe to the waiting area, no manual feeding.

Fiber Laser Pipe Cutting Machine

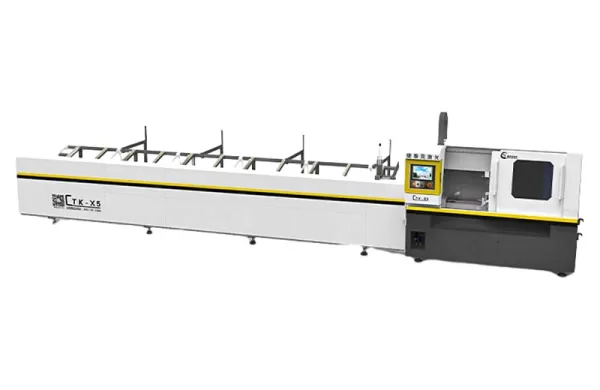

- Model: CTK-X5

- Round Tube: φ10mm – φ115mm

- Processing Length Range: φ15mm – φ1000mm (Other lengths can be customized)

- Cutting Speed: 12m / min (Depending on the material and thickness)

- The transmission part of the feeding system has a compact structure, avoid the superposition of deformed pipes and causes the material to get stuck.

- Model: CTK-C8-LN

- Round Tube: φ20mm – φ360mm

- Square Tube: φ20mm – φ250mm

- Rectangular Tube: φ300mm × φ200mm

- The front chuck is well sealed to avoid cutting dust. The rear chuck automatically blows air, and the pipe wall is cleaner.

- The main machine bed is welded with plate and tube, conforms to the mechanical structure and has good cutting stability.

Fiber Laser Tube Cutting Machine

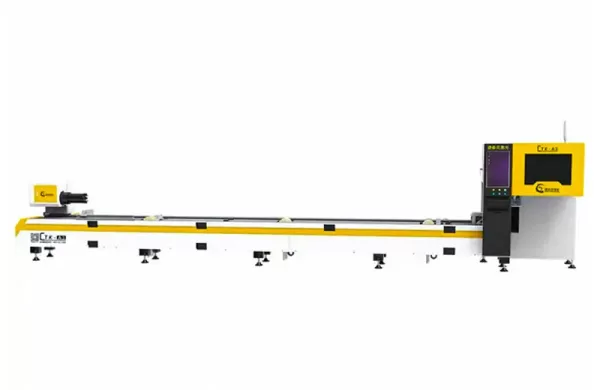

- Model: CTK-X2-LD

- Round Tube: φ16mm – φ65mm

- Processing Length Range: φ15mm – φ1000mm (Other lengths can be customized)

- Cutting Speed: 12m / min (Depending on the material and thickness)

- Operators can operate two machines in the same channel, improving work efficiency.

Fiber Optic Laser Cutting Machine

- Model: CTK-C6

- Round Tube: φ15mm – φ220mm

- Rectangular Tube / Square Tube / Special-shaped Tube: Circumscribed Circle ≤ φ220mm

- 1000W-3000W fiber laser cutting, high precision, fast speed.

- Professional full-stroke pneumatic chuck, good sealing, dustproof and durable.

Industrial Fiber Laser Cutting Machine

- Model: CTK-X15-E

- Round Tube: φ16mm – φ80mm

- Rectangular Tube: φ16mm × φ16mm – φ60mm × φ60mm (Diagonal less than 85mm)

- Automatically process the head and tail of the material, avoid mixing with defective products.

- High precision chuck, speed up to 150 RPM or more.

Laser Cutting Machine for Pipe

- Model: CTK-C13

- Round Tube: φ15mm – φ350mm

- Rectangular Tube / Square Tube / Special-shaped Tube: Circumscribed Circle < φ350mm

- Max. Speed of Chuck: 70r / min

- Intelligent pipe cutting system, improve cutting efficiency.

Laser Cutting Machine for Tubes

- Model: CTK-A3

- Round Tube: φ15mm – φ160mm

- Rectangular Tube / Special-shaped Tube: Circumscribed Circle ≤ φ160mm

- Optional slag extraction system, ensure that the inner wall of the pipe without residue.

- Stable and fast feeding, cycle time is about 10 seconds.

- Model: CTK-X6-LD

- Round Tube: φ40mm – φ115mm

- Processing Length Range: φ15mm – φ1200mm (Other lengths can be customized)

- Cutting Speed: 12m / min (Depending on the material and thickness)

- Suitable for cutting heavy pipes, such as compressors, air conditioning pipes, etc.

Metal Fiber Laser Cutting Machine

- Model: CTK-X13-E

- Round Tube: φ8mm – φ80mm

- Rectangular Tube: φ10mm × φ10mm – φ60mm × φ60mm (Diagonal less than 85mm)

- Independently developed bus system, simple operation, providing remote troubleshooting and system upgrade services.

- High-speed 3D cutting, 1.5G acceleration, chuck speed up to 150RPM, cutting, drilling, slotting efficiency.

Metal Pipe Laser Cutting Machine

- Model: CTK-C7-LN

- Round Tube: φ12mm – φ220mm

- Square Tube: φ12mm – φ160mm

- Kerf Width: 0.1mm – 0.2mm

- Fiber Diameter: 20μm

- Model: CTK-X15

- Round Tube: φ16mm – φ80mm

- Rectangular Tube: φ16mm × φ16mm – φ60mm × φ60mm (Diagonal less than 85mm)

- Maximize pipe utilization, tail material > 40mm, save more cost.

- Automatic feeding system, storage capacity of up to 2 tons, fast and accurate feeding.

Metal Tube Laser Cutting Machine

- Model: CTK-X13

- Round Tube: φ8mm – φ80mm

- Rectangular Tube: φ10mm × φ10mm – φ60mm × φ60mm (Diagonal less than 85mm)

- Chuck clamping speed is fast, can adjust the clamping force, to achieve non-stop loading and unloading, improve efficiency.

- Anti-scratch design of feeding system, prevent friction and scratch of pipe surface.

Round and Square Tube Laser Cutting Machine

- Model: CTK-C1

- Round Tube: φ15mm – φ160mm

- Rectangular Tube / Square Tube / Special-shaped Tube: Circumscribed Circle < φ160mm

- With three-chuck structure, there are almost no remnants when cutting, saving the cost of materials.

- 3D cutting to meet your various pipe production needs.

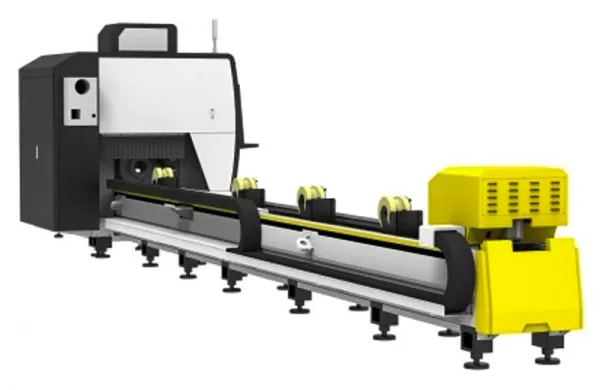

Sheet and Tube Laser Cutting Machine

- Model: CTK-3015FB

- Round Tube: φ20mm – φ220mm

- Rectangular Tube / Square Tube: Diagonal ≤ 220mm

- Cutting Speed: 80m / min

- Customized laser generator, small slit, low energy consumption.

Tube and Plate Laser Metal Cutting Machine

- Model: CTK-3015F

- Round Tube: φ20mm – φ220mm

- Rectangular Tube / Square Tube: Diagonal ≤ 220mm

- Cutting Speed: 80m / min

- CNC system controls servo motor to ensure good cutting quality.