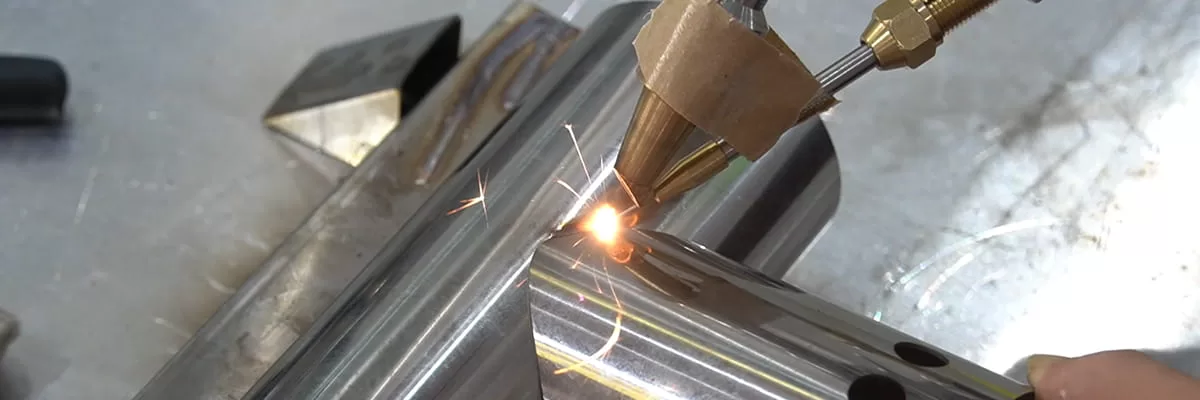

Handheld Laser Welding Machine

If you need to weld micro parts with high accuracy, using a handheld laser welding machine is most suitable.

The fiber laser beam is focused on the workpiece, generating heat to melt and bond the metal, enabling precise welding.

Chittak provides portable handheld laser welders with laser power of 1000W – 2000W for welding stainless steel, aluminum, iron and other metal materials.

Handheld Laser Welding Machine Features

High Efficiency: The welding speed is 2x – 10x that of traditional welding (MIG & TIG welding) equipment.

Save Cost: Laser welding produces a small heat-affected zone, avoids thermal distortion. No need for secondary grinding and machining, saving time and manpower.

Easy to Operate: User-friendly interactive interface. Operators can easily adjust parameters such as laser power, welding mode and duration.

Versatility: It is suitable for industries requiring precision welding such as household appliances, medical devices, automotive and aerospace, etc.

Weld Method: Our handheld laser welding machine adopts four welding methods, namely, flat position welding, horizontal position welding, vertical position welding and overhead position welding.

1000W Handheld Laser Welding Machine

- Model: CTK-HJ1000

- Laser Wavelength: 1064nm – 1080nm

- Spot Adjustment: 0.2mm – 5mm

- Fiber Length: Standard 10m

- Welding Speed Range: 0mm/s ~ 120mm/s

- Model: CTK-HJ1500

- Welding Thickness: 0.5mm – 2 mm

- Welding Gap: ≤ 0.5mm

- Wire Feeding Method: Automatic / Manual

- Wire Feeding Type: Stainless Steel Wire, Iron Wire, Aluminum Wire

2000W Handheld Metal Laser Welding Machine

- Model: CTK-HJ2000

- The spot width can be adjusted, and the welding fault tolerance is strong, which makes up for the disadvantage of small laser welding spot.

- It is easy to weld any part of the workpiece at any angle.

- The welding speed is 2x – 10x that of traditional welding equipment.