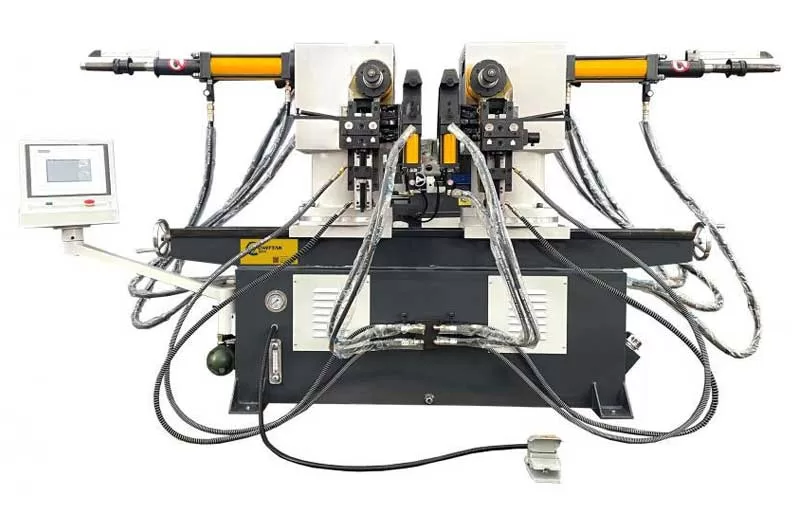

CNC Tube Bending Machine

Model No. : CTK-38CNC-4Z-2S

Payment Type : T/T, Others

Incoterms : FOB, CIF, EXW

Min. Order : 1 Set

Transportation : Ocean

Port : Foshan Port, Guangzhou Port, Shenzhen Port

Robust construction for longevity in CNC bending

Boasts a robust and durable construction designed to withstand the rigorous demands of CNC tube bending operations.

Minimizes downtime by ensuring longevity and reliability in bending applications.

Customizable CNC bending parameters for tailored results

Allows operators to customize bending parameters using the CNC system, adapting to specific project requirements.

Provides flexibility and adaptability to varying tube materials and thicknesses through precise CNC adjustments.

Excellence in CNC tube bending technology

Upholds the tradition of precision in CNC tube bending technology, delivering exceptional results through advanced CNC control.

Sets a benchmark for craftsmanship in tube bending with the revolutionary CNC Tube Bending Machine CTK-38CNC-4Z-2S.

| Max. Bending Diameter for Carbon Steel | ф38mm * 2.0 |

| Max. Bending Radius | R175mm |

| Min. Bending Radius | Based on the pipe diameter |

| Min. Bending Angle | 190° |

| Standard Core Length | 2000mm |

| The Number of Bends Can be Set Per Pipe | 20 |

| Max. Feeding Length | 2000mm |

| Control System | PLC |

| Machinable Material | Carbon Steel |

| Core Components | PLC, Bearing, Motor |

| Power Type | CNC |

| Degree Of Automation | Automatic |

| Solenoid Reversing Valve Brand | Yuken |

| Relief Valve Brand | Yuken |

| Regulating Valve Brand | Yuken |

| Sensor Brand | Omron |

| Cylinder Brand | Hualiang |

| Microcomputer Control System Brand | Delta |

| Switch Brand | Meanwell |

| AC Contactor Brand | Schneider |

| Thermal Overload Relay Brand | Schneider |

| Precision Ball Screw Brand | TBI |

| Certification | GS |

| Warranty Period | 1 Year |

| Core Component Warranty Period | 2 Years |