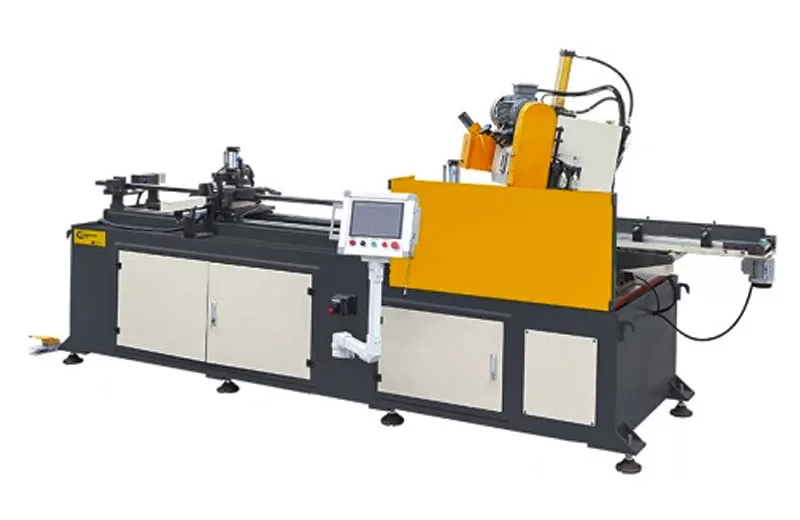

CNC Circular Saw Pipe Cutting Machine

Model No. : CTK-450CNC-3Z

Payment Type : T/T, Others

Incoterms : FOB, CIF, EXW

Min. Order : 1 Set

Transportation : Ocean

Port : Foshan Port, Guangzhou Port, Shenzhen Port

Cutting-edge CNC circular saw technology

Employs advanced CNC circular saw technology for unparalleled precision in pipe cutting applications.

Versatile pipe material compatibility

Engineered to handle a diverse range of pipe materials, offering versatility in cutting applications.

Ideal for precision cutting of various pipe profiles and dimensions.

Efficient and high-precision pipe cutting

Powerful cutting capabilities for efficient, high-precision pipe cutting operations.

Ensures superior cut quality, minimizing material wastage and optimizing production output.

Sturdy construction for durability

Features a robust and durable construction designed to withstand the demands of heavy-duty pipe cutting operations.

Enhances equipment longevity and reduces maintenance requirements.

User-friendly interface and controls

Intuitive user interface and controls for seamless operation, ensuring quick adaptation by operators.

Improves operational efficiency and reduces training time for enhanced productivity.

Enhanced safety protocols

Integrates advanced safety features to establish a secure working environment during pipe cutting operations.

Adheres to stringent safety standards, prioritizing operator safety.

Precision angular pipe cutting capabilities

Demonstrates precision in angular pipe cutting, catering to industries with exacting requirements for angular cuts.

Streamlined production efficiency

Streamlines pipe cutting processes, significantly boosting overall production efficiency.

Facilitates faster production cycles without compromising on the precision of pipe cuts.

Compliance with stringent industry standards

Meets or exceeds industry standards, ensuring reliability and alignment with the latest technological advancements.

Sets a new benchmark for CNC circular saw pipe cutting machines, combining cutting-edge precision with versatile functionality.

| Cutting Capacity (Single Mild Steel Pipe) | Head Swivel | 45° / 90° / 135° |

| Round Tube | Φ20mm – Φ80mm | |

| Square Tube | 80mm * 80mm | |

| Max. Rectangular Tube | 80mm * 60mm | |

| Tail End Material Length | ≥ 100mm | |

| Max. Width Between Clamps | 120mm | |

| Feeding Length (Multiple feeding is available) | 1900mm | |

| Tail End Material Length | 100mm | |

| Saw Blade Diameter | HSS / TCT φ250mm – φ400mm | |

| Pin Holes | φ32 / 4 – φ11 × PCD63, φ50 / 4 – φ15 × PCD80 | |

| Hydraulic Drive Pressure | 25Kg/cm2 – 35Kg/cm2 | |

| Oil Tank Capacity | 90L | |

| Net Weight | 6600Kg | |

| Machine Diameter (LxWxH) | About 11300mm x 2400mm x 1800mm | |

| Degree Of Automation | Automatic | |

| Driven Model | Automatic | |

| Machinable Materials | Brass / Copper, Stainless Steel, Carbon Steel, Aluminium Alloy | |

| Core Components | Gear, Motor | |

| Servo Motor Brand | Delta | |

| Oil Pressure Regulating Valve Brand | Yuken | |

| Hydraulic Workstation Brand | Chittak | |

| PLC Brand | Mitsubishi | |

| Warranty Period | 1 Year | |

| Core Component Warranty Period | 2 Years | |